New heated armrest from Yanfeng Automotive Interiors offers additional comfort and convenience

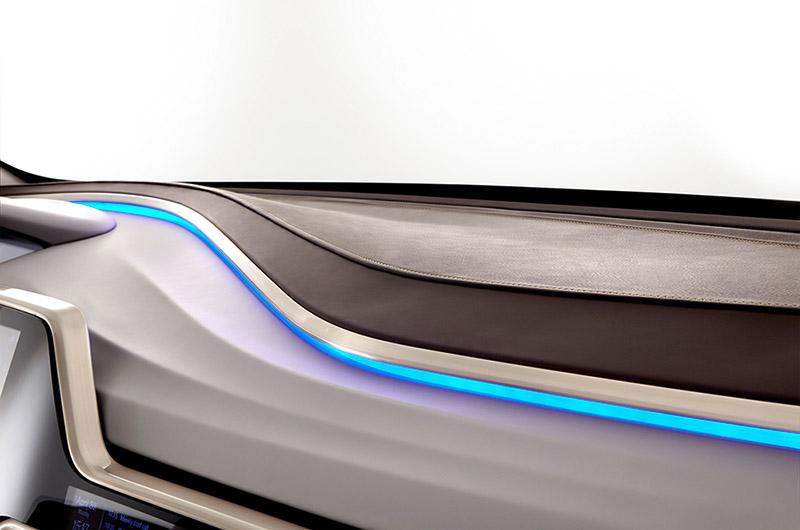

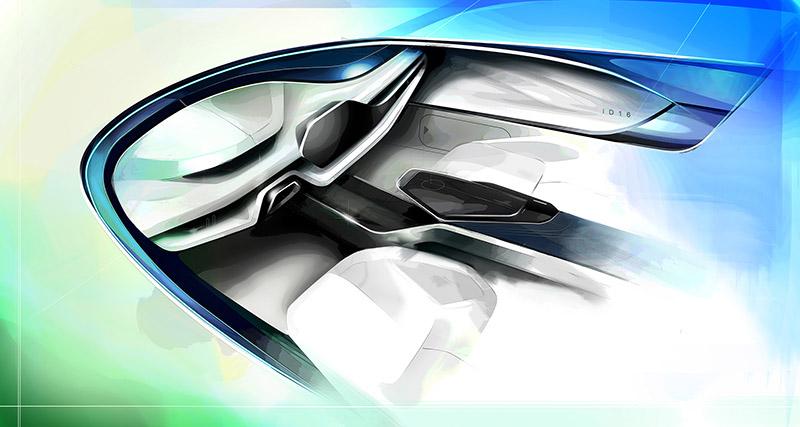

Yanfeng Automotive Interiors (YFAI) has developed a new heated armrest for door panels. Comfort, personalization, energy efficiency and production flexibility drove the development of this new generation of heated armrests. Thinner and lighter weight than comparable products currently on the market, the heated armrest provides benefits in terms of energy efficiency. With this the company can offer automakers a cost-effective feature which can easily be integrated into existing door panel production lines.

Even with the heat on full speed, you can still feel uncomfortable in the car – especially on cold winter days. The cold air outside and inside the vehicle leave us shivering when getting into the car, even with a warm jacket. In order to enhance the comfort factor inside the car, YFAI has redefined heated armrest technology for door panels.

The heated armrest uses a panel heating technology system. Panel heating systems are not only extremely comfortable, but also highly energy efficient. The heat they produce reaches passengers more directly and quickly than the heat emitted by conventional vehicle HVAC systems. As a result, the driver can lower the heat coming from the HVAC system when using the heated armrest.

The new heated armrest is ready for series production. The functional panel can easily be integrated into the existing door panel production process. This solution is cost-effective, as it uses the same equipment, foam carrier and materials as conventional, unheated armrests. Therefore, heated armrests can be produced on the same production line as conventional armrests in a single just-in-sequence process.

Energy-efficient comfort, also for e-mobility applications

Significantly lighter in weight and thinner than the solutions currently on the market, the innovative heating foil requires less energy for improved efficiency.

“Our vision with this product was to offer increased comfort during the winter months. The new heated armrest can be integrated into all door panels in the vehicle,” said Han Hendriks, vice president Advanced Product Development & Sales at Yanfeng Automotive Interiors. “With this innovation, we also are responding to increased demand for new kinds of comfort solutions in the vehicle.”

The technology also can be integrated into floor console armrests in addition to door panels. The heated armrest is also an ideal heating source for use in electric cars, as the power is supplied electrically.

LinkedIn

LinkedIn

Instagram

Instagram

YouTube

YouTube