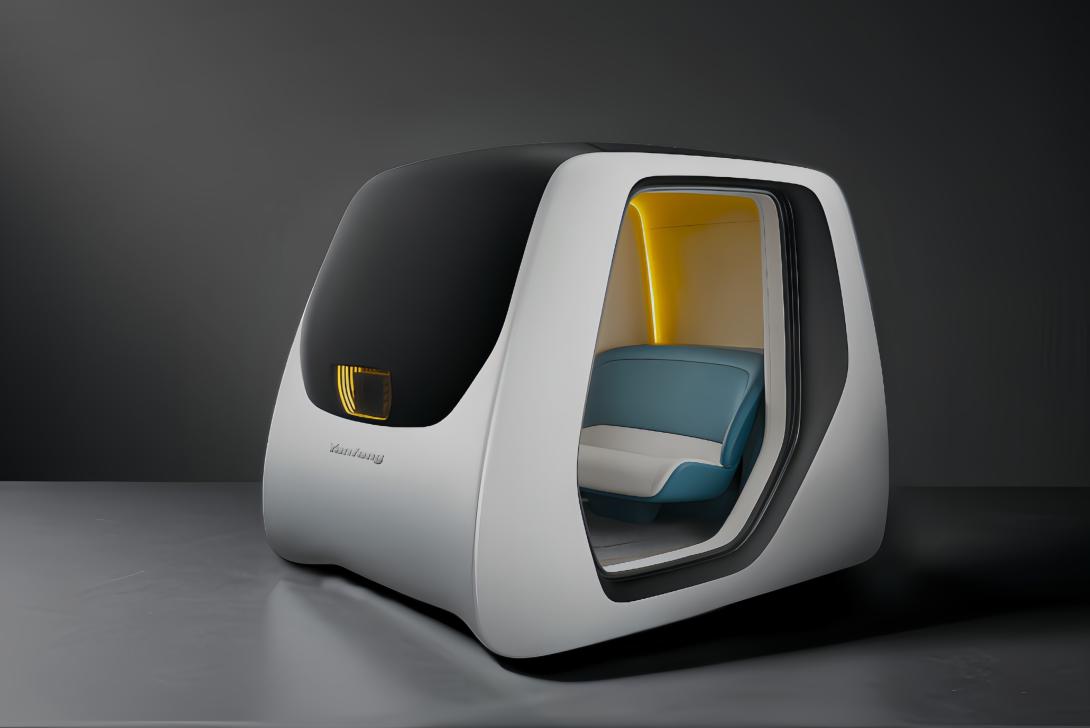

At CES Yanfeng introduces next generation of its Hover Seat that features occupant sensing

At CES, Yanfeng, a leading global automotive supplier, introduced a new generation of its Hover Seat, with Seat Sensing Posture ID technology that adds new levels of comfort.

The seat based on zero gravity research, by detecting the occupant’s body language, such as seating position, level of fatigue, and body type actively releases fatigue for passengers throughout the ride and to improve the driving experience.

Adaptive Welcome Mode for Different Body Types

When a passenger gets into the car, the pressure pad sensors accurately recognize information about the body type and automatically adjust the headrest, lumbar support and side wings to make the seat closely fit to the body.

Seating Position Recognition and Fitting

The sensor determines the seating posture of the occupant based on the pressure distribution to the seat. Equipped with a matrix of multi-faceted support blocks, the seat automatically adjusts the blocks to give comfortable support to the body where needed.

Fatigue Detection and Automatic Massage

The seat detects the occupant changing their posture over time, then determines the degree and location of fatigue, and automatically triggers the partition massage function.

In addition, when driving or riding for an extended period and needing to stop and rest, the seat features weightless relaxation in Zero Gravity mode, which allows passengers to recline the seat up to 126° (angle torso to thighs) at the touch of a button. The backrest can be fully reclined, creating a feeling of weightlessness that allows passengers to unwind.

“Yanfeng has taken the Hover Seat to new levels of comfort with the Seat Sensing Posture ID technology,” said Patrick Nebout, CTO of Yanfeng Technology. “The seat will actively provide tailored comfort adjustments for users with different body types and sitting postures and will actively alleviate passenger fatigue and enhance the travel experience.”

The next generation of the Hover Seat can also integrate features from the first generation. This includes optional functions including seat heating and ventilation, or an electric four-way adjustable headrest, integrated sound system, and others.

As with the original version, the functionality of the seat can be tailored to automaker needs, such as the choice of rotation, horizontal movement, manual or electric long rails.

LinkedIn

LinkedIn

Instagram

Instagram

YouTube

YouTube